It appears that government is expecting the impossible from South Africa's vehicle manufacturers.

SA has attracted precious little fixed manufacturing investment in the last few years. The calibre of investment in SA creates employment in the sector, but there are problems because some workers do not always have the required skills.

Investment growth in SA

The country's once mighty mining industry is in seemingly inexorable decline and the manufacturing which has traditionally supported South Africa's deep-level resource exploitation has suffered.

READ: Local is lekker: SA-built BMW X3's ready for export to Europe

There is an argument to be made that the only quality manufacturing jobs which have been created in the last few years, are the result of handsome investment by the motor industry.

Domestically, our market is dominated by brands which build here and the Korean twin importers: Hyundai and Kia. All others have suffered from the volatility of rand denominated imports.

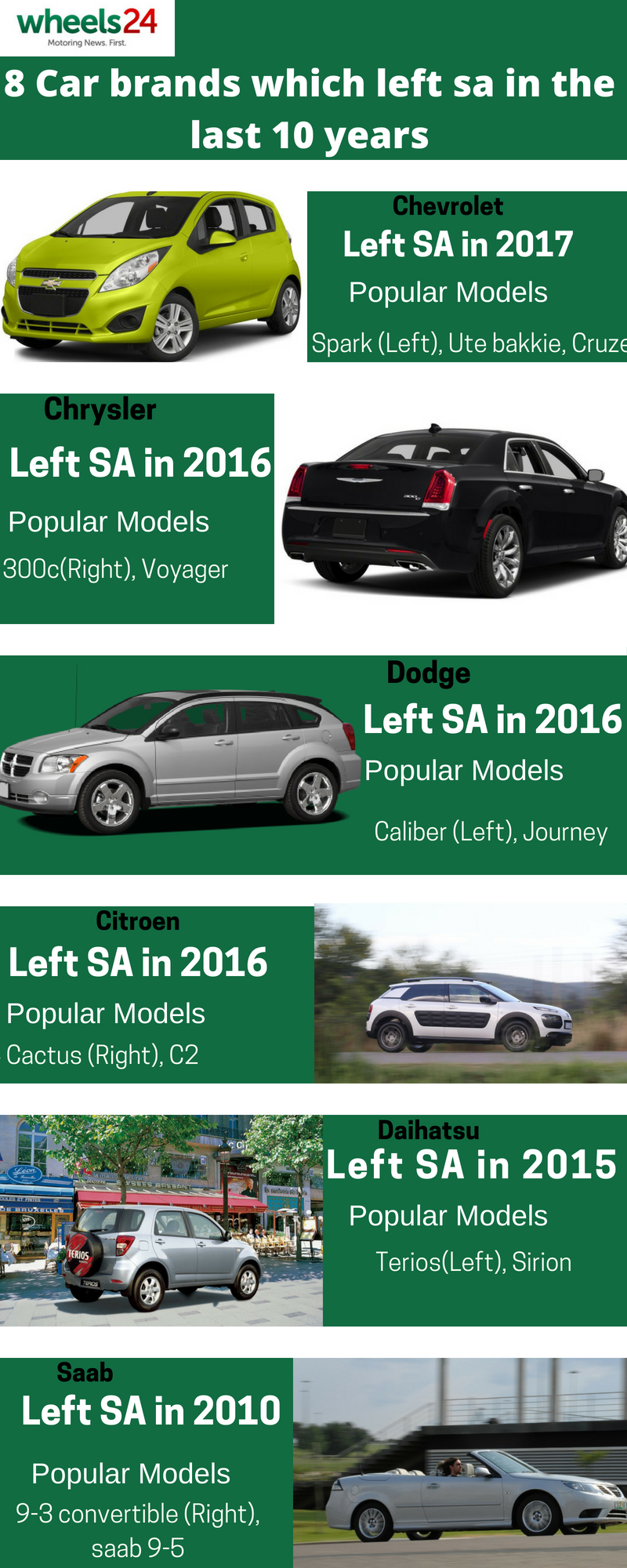

In the last few years a host of Chinese brands have dissolved their South African operations and the retreat of Chevrolet, Chrysler and Citroen signalled exactly how profit-pressured the local automotive business can be.

Bleak motoring past

It's worth remembering that Chevrolet was an anchor local manufacturer in the 1960s and 1970s, as was Chrysler. Both are now part of South Africa's motoring history, not its present - or future.

Just as unfavourable commodity prices, labour wage demands and exchange rate volatility have closed many mines in the South African resource sector over the last decade, the same logic applies to automotive manufacturing.

Image: AFP

No brand is immune to failure.

If the numbers don't add-up or incentives become unattractive, brands will decommission factories and find additional capacity somewhere else in their global production footprint.

BMW, Ford, Mercedes, Nissan, Toyota and VW have all invested billions in their local assembly facilities of late, upskilling workers and guaranteeing stability of employment.

SA still successful

Despite a massive geographic disadvantage, SA's export orientated motor manufacturing is well regarded globally and seemingly successful.

The incentive agreements which have always advantaged those manufacturers who build here, as opposed to pure importer and distribution brands, is up for renegotiation in 2020 and government is adding pressure with some very lofty expectations.

SA suffers from a critical unemployment issue and government is expecting the motor industry to help solve this by increasing current exports, which at 600 000 vehicles per year are larger in size than total domestic new car sales.

Image: BMW Group

The uncomfortable truth is that SA automotive production, although high quality, is also exhaustively labour intensive - many times more so than other comparable locations.

Government's hope for South African automotive assembly to absorb twice the amount of labour it currently does, is an impossibility - even if export volumes increase by 100%.

More cars, fewer people

Mechanisation and automation is increasingly reducing the number of required assembly line jobs globally. Advances in technology mean you can build a lot more cars, with fewer people.

Government's hope of increasing locally built automotive manufacturing from 600 000 to 1.5 million units by 2035 won't correlate to adding nearly 300% more jobs.

There has always been a contention about the advantages enjoyed by those brands which manufacture locally.

The truth of the matter is that without a local automotive production, South Africa's unemployment would be far worse - and the logic is that most consumers dutifully sacrifice on price, paying a bit more for their cars in a trade barrier market, thereby contributing to reducing local unemployment.

The local car market is certainly not a free and open, but SA is a unique case regarding its history and as such those brands which have invested hugely in infrastructure and development here, feel government is obliged to reward them.

Considering the absence of any other fixed manufacturing investment in South Africa, government should cherish the local automotive industry, instead of setting impossible demands.

By 2035 the local industry could well be building 1.5 million cars a year, but the improvement in manufacturing technology and methods of efficiency between then and now will likely reduce the number of workers required, instead of doubling it - as government imagines.

Titanic is a clear analogy for the risk of expecting too much from a manufacturing industry.

It took 3000 shipbuilders to construct Titanic in 1912.

Last year Royal Caribbean launched its Symphony of the Seas, a ship five times the size of Titanic, built by only 2 500 workers. The influence of automation on labour, is startlingly real.

Publications

Publications

Partners

Partners