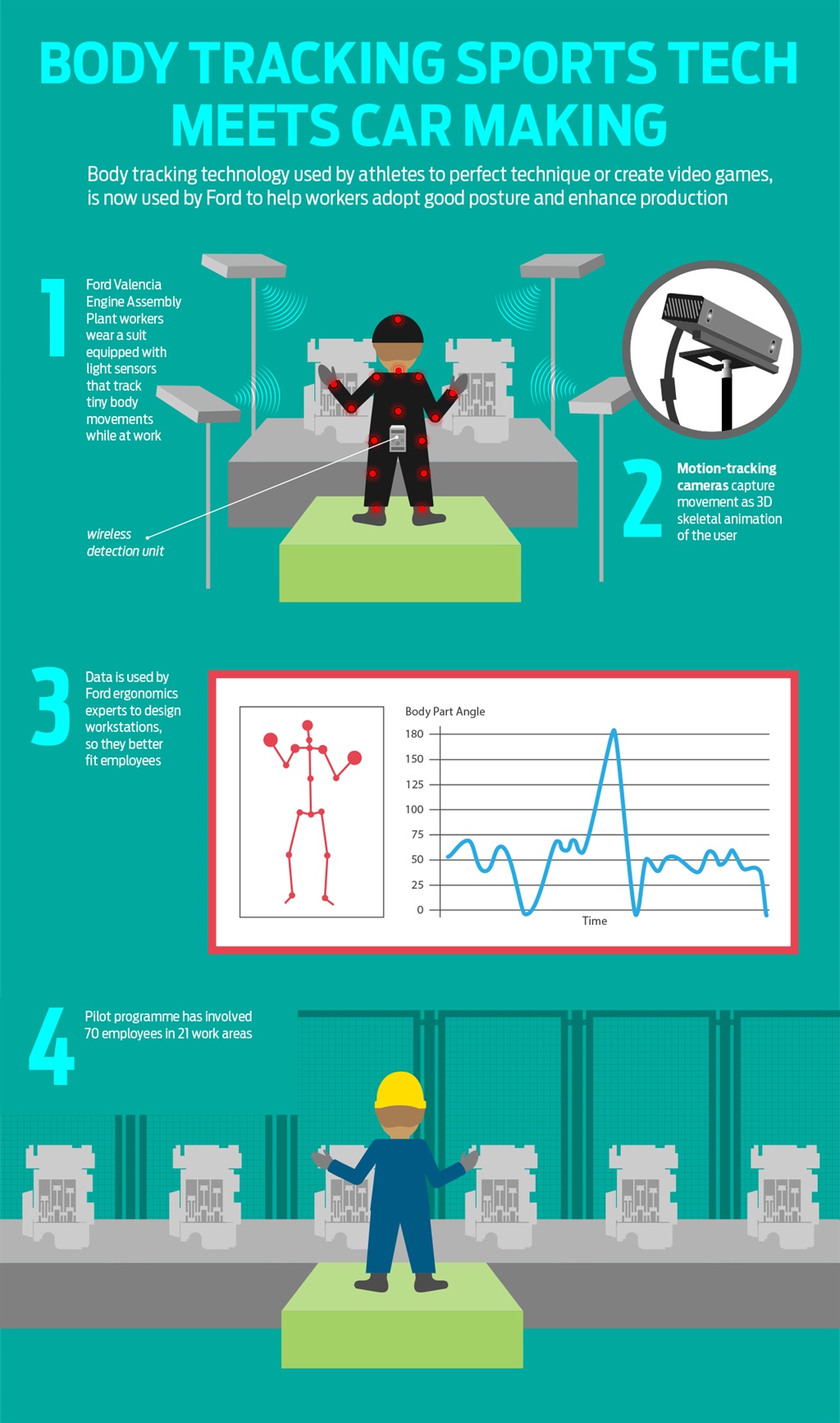

Employees at Ford’s Valencia Engine Assembly in Spain, are using a special suit equipped with advanced body tracking technology. The pilot system, created by Ford and the Instituto Biomecánica de Valencia, has involved 70 employees in 21 work areas.

Player motion technology usually records how athletes sprint or turn, enabling sport coaches or game developers to unlock the potential of sport stars in the real world or on screen. The automaker is using it to design less physically stressful workstations for enhanced manufacturing quality.

Motion tracking tech

Javier Gisbert, production area manager, Ford Valencia Engine Assembly factory: "It’s been proven on the sports field that with motion tracking technology, tiny adjustments to the way you move can have a huge benefit.

"For our employees, changes made to work areas using similar technology can ultimately ensure that, even on a long day, they are able to work comfortably."

Watch the video here:

Engineers took inspiration from a suit they saw at a trade fair that demonstrated how robots could replicate human movement and then applied it to their workplace, where production of the new Ford Transit Connect and 2.0-litre EcoBoost Duratec engines began in July.

The skin-tight suit consists of 15 tiny movement tracking light sensors connected to a wireless detection unit. The system tracks how the person moves at work, highlighting head, neck, shoulder and limb movements. Movement is recorded by four specialised motion-tracking cameras – similar to those usually paired with computer game consoles – placed near the worker and captured as a 3D skeletal character animation of the user.

Part of the plan to reduce injury rate

Specially trained ergonomists then use the data to help employees align their posture correctly. Measurements captured by the system, such as an employee’s height or arm length, are used to design workstations, so they better fit employees.

Ford is now considering further rollout to its other European manufacturing facilities. It is part of Ford’s work – underway since 2003 – to reduce the injury rate for its employees worldwide through the introduction of ergonomics technologies and data-driven process changes.

Ford Valencia Engine Assembly Plant workers wear special suit with sensors that helps promote good posture

The company is considering further rollout to its other European manufacturing facilities.

Image: The Newsmarket

Publications

Publications

Partners

Partners